Known worldwide for CITCO Tools & Gardner Abrasives custom-engineered tooling solutions, Fives designs and supplies high-precision PCD and PcBN cutting tools, diamond dressing tools and abrasive and superabrasive grinding wheels.

Fives offers the most valuable technologies in the industry to exceed customer objectives in terms of precision, high-performance, reliability and return-on-investment.

CITCO PCD & PcBN Cutting Tools

High-precision tooling solutions for the most complex cutting applications.

CITCO natural, CVD & Peerless Diamond Dressing Tools

Custom-engineered dressing solutions for maximum abrasive performance.

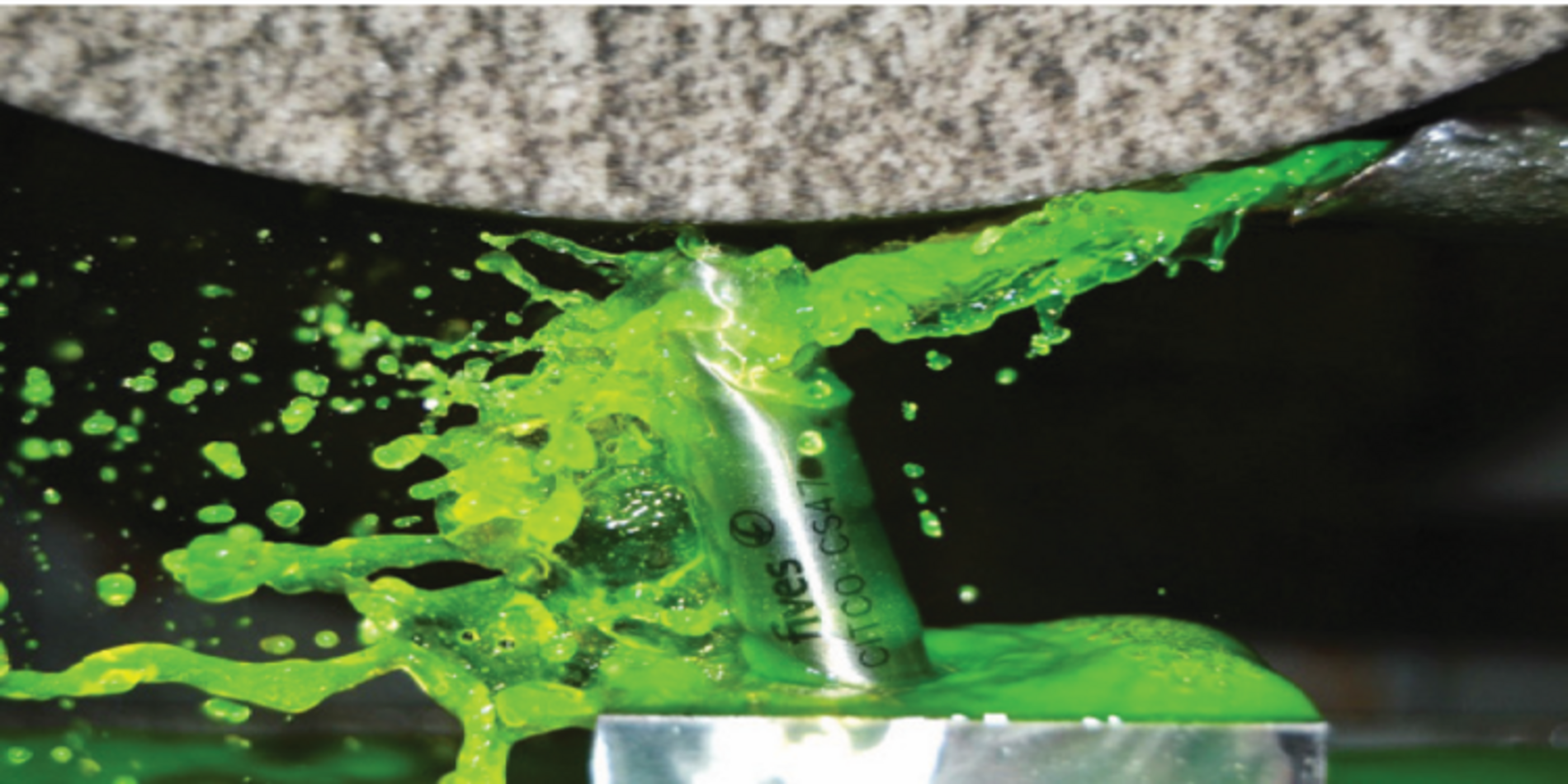

Gardner Abrasives & Superabrasive Grinding Wheels

Quality and reliable abrasive solutions for disc, fine, OD and tool & cutter grind applications.